Vibrate Knife Cutting Machine china vibrate knife cutting machine

The vibrating knife is currently a relatively widely used processing equipment in the cutting process of flexible materials. It uses the upper and lower high frequency vibration of the blade to cut, gradually improving or replacing the traditional flexible cutting process equipment.

Advantages

Simple operation, high efficiency, Environmentally friendly and odorless

1. The cutting process has no peculiar smell. The vibrating knife cutting machine uses a very sharp blade to cut, and does not produce a pungent smell.

2. The cutting edge is flat and smooth, and the cutting surface is very neat to facilitate the later processing of the product.

3. The cutting speed is very fast. Due to the blade cutting, the vibrating knife cutting machine can cut flexible materials very fast.

4. The operation is simple, and the automatic cutting method eliminates the need for manual assistance to cut, which virtually saves some unnecessary human resources.

5. Taiwan square rail guide, smooth operation, high precision, long life.

6. The precision of the grinding rack can reach level 5, the pitch error of the phase lead is 0.003mm, and the cumulative error is 0.035mm (1000mm length). Rack specifications: modulus 1-12, with straight and helical teeth, helical helix angle 19 degrees 31 minutes 42 seconds, pressure angle 20 degrees, 500mm/1000mm rack side has mounting holes and positioning pin holes.

7. RUIDA control system is a knife cutting controller independently developed by Ruida Technology with the function of tool direction following control. It integrates the processing of tools such as vibrating cutters, round cutters, milling cutters, and pressing wheels. It also integrates feeding and circular punching. , V-shaped special punching, brush processing, red light positioning and a series of functions.

8. Vibrating knife cutting machine vacuum adsorption work surface: partition adsorption selection: according to the size of the material, the size of the pattern selects the partition dense

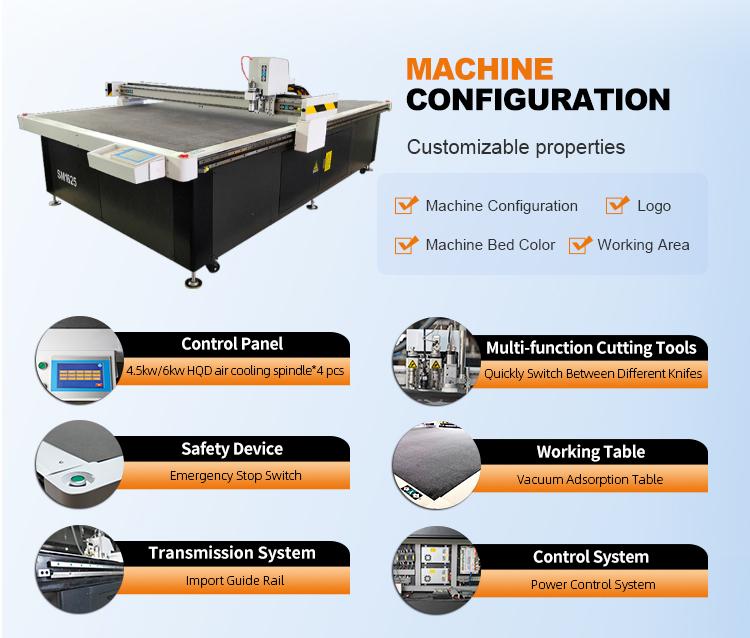

Specification of SuperStar Vibrate Knife Cutting Machine

|

Parameter model |

CX-1625 |

|

Effective working area |

1600*2500mm |

|

Cutting speed |

Up to 800-1300mm/s |

|

Machine size |

2200*3500*1500mm (width, length and height) |

|

Work characteristics |

The computer operation and the cutting machine are carried out at the same time, and the data transmission is completed quickly |

|

Cutting application |

Leather, PVC, fabric, silk circle, EVA, XPE, blended materials, quilted embroidery, velvet materials, etc. |

|

Material fixing method |

Vacuum adsorption |

|

Operation panel |

Touch control system |

|

Cutting accuracy |

±0.01 |

|

Transmission parts |

Taiwan linear guide, Taiwan transmission rack |

|

Motor |

Taiwan Delta Servo Motor |

|

Working voltage/frequency |

380V+10%, 280V+10%, 50HZ+10% |

|

Security configuration |

Intelligent anti-collision switch, emergency stop button |

Applicable Industry

Paper-plastic packaging, leather, PU, PVC, Oxford cloth, corrugated paper, KT board, seats, rubber, gaskets, furniture, textile, metal, electronics and other flexible materials.

If you want to know the latest news about the Fiber Laser Engraving Machine, 30w Fiber Laser Engraver manufacturers, please come to our website and get a quote for free.

https://www.cncroutercn.com/product-vibrate-knife-cutting-machine.html

Payment Terms︰ FOB,CIF,CFR